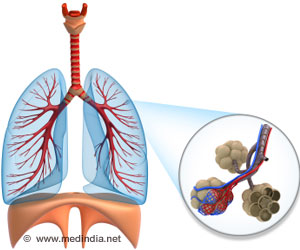

These gourd-like structures, while far less refined, allow the lizard to exchange oxygen for waste gases just as human lungs do. And because they grow quickly by leveraging simple mechanical processes, anole lungs provide new inspiration for engineers designing advanced biotechnologies.

“Our group is interested in understanding lung development for engineering purposes,” said Celeste Nelson, the Wilke Family Professor in Bioengineering and the study’s principal investigator.

While avian and mammalian lungs develop great complexity through endless branching and complicated biochemical signaling, the brown anole lung forms its relatively modest complexity through a mechanical process.

The findings of the study are published in the journal Science Advances.

The anole lung starts a few days into development as a hollow, elongated membrane surrounded by a uniform layer of smooth muscle.

During development the lung cells secrete fluid, and as they do so the inner membrane slowly inflates and thins like a balloon. The pressure pushes against the smooth muscle, causing it to tighten and spread apart into fiber bundles that ultimately form a honeycomb-shaped mesh.

Fluid pressure continues pushing the stretchy membrane outward, bulging through the gaps in the sinewy mesh and forming fluid-filled bulbs that cover the lung.

Those bulges create lots of surface area where the gas exchange occurs. And that’s it. The whole process takes less than two days and is complete within the first week of incubation. After the lizard hatches, air comes in at the top of the lung, swirls around the cavities, and then flows back out.

For engineers looking to crib nature’s shortcuts on behalf of human health, this speed and simplicity make for a radically new design paradigm.

The study also breaks new ground for scientists to study reptile development in far greater detail.

To adapt the exquisite complexity of avian lungs for tools that could benefit human health, researchers believed science needed to go even deeper.

In less than two days, the organ goes from a flat balloon to a fully formed lung. And the process is simple enough that Palmer could use his computational model to build a working replica in the lab. While the engineered system didn’t match the living system’s full complexity, it got close.

Researchers cast the membrane using a silicone material called Ecoflex, commonly used in the film industry for makeup and special effects.

They then encased that silicone with 3D printed muscle cells to create the same kinds of corrugations in the inflated silicone that Palmer had found in the living organ. They met technical barriers that limited their creation’s verisimilitude, but they ended in an uncannily way similar to the living organ.

Those humble backyard lizards had inspired a new kind of artificial lung and a framework that engineers can refine toward unknowable future ends.

Source: Medindia